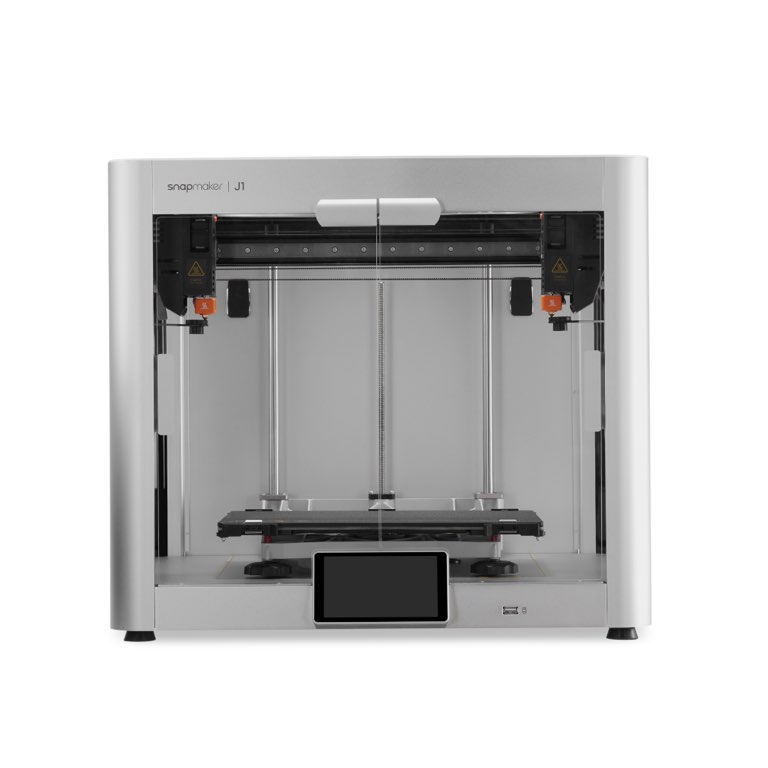

Snapmaker J1 3D Printer

1 699,00 € 1 699,00 € Sisältää ALV:n

1 699,00 € Sisältää ALV:n

Snapmaker J1 3D Printer sisältää itsenäisen kaksoisekstruuderin (IDEX), erittäin nopean tulostusnopeuden ja tasoituksen optimoinnin

Tuotteet sijaitsevat omassa varastossa Suomessa.

Tilaustuote sijaitsee toimittajan varastossa

Ilmainen toimitus yli 100€ ostoksille poislukien tilaustuotteet.

Ennen klo 14 tehdyt tilaukset lähetetään saman päivän aikana. HUOM! Tilaustuote merkitty tuote toimitetaan toimittajan varastosta 3-5 arkipäivässä ja tuotteen toimituskulut lasketaan ostoskorissa.

Toimitusehdot

Snapmaker J1 3D Printer

The Snapmaker J1 3D Printer features an independent dual extruder (IDEX), ultra-fast print speeds, and smoothness optimization. With molded and machined parts, linear rails, intuitive software, and a user-centric design, the J1 is also sophisticated and robust.

Highlights:

- Dual-material printing

- Breakaway supports and dissolvable supports for effortless removal

- Copy mode and mirror mode double your productivity

- Up to 350 mm/s print speed and up to 10,000 mm/s² acceleration

- Extreme rigidity from one-piece die casting, high-precision linear rails and aluminum alloy frame

- 5-inch intuitive touchscreen

Fast index printing

Compared to a single extruder multi-material unit, IDEX dual material printing requires less time to change filament and produces less waste. In addition, IDEX offers the cleanest dual extruder solution, preventing cross-contamination.

Print in parallel

Halve your wait time, double your productivity. IDEX is the only extrusion system with two separate extruders that move independently on the X-axis, allowing you to print two parts simultaneously.

Copy Mode : Print two identical objects at once. It is especially suitable for batch printing, motivation for studios and hobbyists. If one of the prints encounters a problem, you can pause the printing without affecting the other. This mode is a lifesaver for promised delivery under tight deadlines.

Mirror Mode : The J1 directly mirrors your design and prints the original and mirrored version in one go. In a symmetrical design, you can import half of it and print it in mirror mode to reduce waiting time by 50%, perfect for quick sketches and concept designs. As with copy mode, you can stop one print without affecting the other.

Vibration compensation

The J1 offers a top-notch 350mm/s print speed while ensuring high print resolution. This is possible thanks to the optimization of vibration compensation technology. This technology reduces vibration caused by fast movements and minimizes ringing noise to improve print quality. With a maximum acceleration of 10,000mm/s², you can realize small models full of details efficiently.

Seamless extruder changeover and angulation optimization

During dual extrusion printing, the inactive extruder preheats in standby mode and starts printing immediately after the active extruder exits, significantly reducing your waiting time. By analyzing the movement directions of the extruders in advance, the J1 can prevent problems such as corner bulges and produce better print quality at corners.

Speed is guaranteed by careful hardware design

One-piece die-casting: The J1’s body consists of an upper frame and a one-piece die-cast base, along with four aluminum alloy bars. Making the body from just a few highly integrated parts—an approach long adopted in the automotive industry—makes for precise assembly. The J1 is so rigid and reliable, with minimal wobble and deformation, that you can print large projects continuously for long periods of time, and get all your prints with uncompromising quality.

High-precision linear rails : Industrial-grade linear rails are CNC-machined to micron levels, ensuring smooth and even movements. Significantly increased accuracy, rigidity, and durability, so you can enjoy a fast, accurate, and smooth manufacturing experience.

Aluminum alloy frame : J1 inherits Snapmaker's iconic all-metal structure, which is highly appreciated by users for its rigidity and durability. It provides better heat dissipation with the motherboard and power supply spread on the base and aluminum alloy as the main material. All electronic components are well oiled, at your command.

Breakaway & Dissolvable supports

Building and removing support can sometimes seem like rocket science, but we’ve done the math for you – flat support, a clean interface, effortless removal, and minimal post-processing required to maintain high dimensional accuracy. Breakaway filament offers the same support as regular materials, but is much easier to remove without additional post-processing. J1 supports PVA and other soluble materials. Soak the print and the supports dissolve, resulting in a smooth surface and excellent dimensional accuracy. When you’re looking for complex geometry, hollow structures, and fine detail, this is the one for you.

Dual-material printing

Get the best of both worlds in one print. Combine the strength of nylon with the flexibility of TPU to create functional parts. Print multi-part objects as well. Without assembly, the object achieves stronger interconnections, making it less susceptible to damage.

Advanced extruder technology

300°C Hot Ends: The 300°C maximum nozzle temperature is convenient when printing with high-temperature filaments such as nylon, reinforced nylon and PC. The silicone hot end socks prevent heat loss, allowing filaments to melt and heat up much faster. Anti-clogging designs ensure the flow is as smooth as possible.

Dual Direct Drive : Excellent extrusion precision, which helps in extruding flexible filaments, and the high sensitivity of dual direct drive, which makes deposition faster, smoother and more precisely controlled. It is built-in with a filament sensor that will notify you and pause the print job if filament runs out, nozzles clog, or other abnormalities that fail to load filament.

Compact Extrusion Path : The uniquely designed compact extrusion path allows you to print seamlessly with TPU and many other flexible materials.

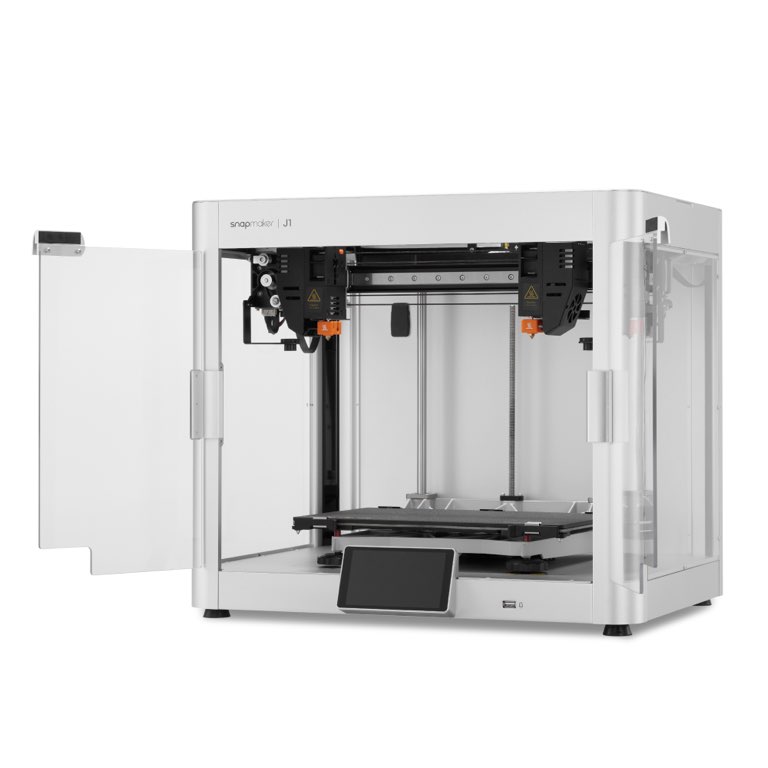

Enclosed Space : Provides stable environmental conditions to facilitate continued reliable performance of high-temperature materials. For example, it prevents warping of ABS and many other materials.

Calibration made easy

We use electrical conductivity to locate two hot ends and a heated layer and measure the distances between three entities – a creative solution to the complex IDEX calibration. With this time saver, you can complete the calibration in 10 minutes in auxiliary mode. Eliminating the calibration card and judgment reduces errors and achieves better accuracy.

Hands-free XY Offset Calibration : When two hot heads touch the square opening of the heated bed, it sends electrical signals to suggest their exact position, and the J1 calculates the offsets between them. The J1 then automatically compensates for the offsets during printing to ensure perfect XY alignment, preventing layer displacement and improving the success rate of bi-material prints. It eliminates the long learning curve and saves you from having to study an awful lot of lines. Tap the start button and calculate backwards for higher accuracy.

Tool-Free Leveling: A flat build plate is the foundation for successful 3D prints, but leveling the bed on IDEX printers can be very time-consuming. Using a PEI glass plate with a high level, the J1 can reduce 3×3 (9-point) or 4×4 (16-point) leveling to 3-point leveling without sacrificing flatness and downtime by 70-80%. Turn the leveling wheel according to the instructions on the touchscreen and the bed will be level for a top-level first layer adhesion.

Easy-to-Manage Z Offset Calibration : Using electrical conductivity, the J1 can calculate the distances between the hot ends and the heated bed. This allowed us to reduce the need to move the calibration card back and forth while adjusting the Z offset. Simply turn the thumbwheel according to the instructions on the touchscreen and you are now a Z offset calibration guru!

Custom PEI Glass Sheet

The J1's build plate is made of glass, which is smooth, so the first layer is smooth and sticky. One side is glossy glass and the other side is a PEI coating, which helps different filaments adhere. The plate is easy to remove, making it especially convenient for maintenance and print removal.

Easily replaceable Hot Ends

Loosen the two hothead screws, attach or replace the hothead and get back to printing in no time. For adventurers looking for more variation and advanced applications, we offer multi-diameter hotheads from 0.2mm for fine detail to 0.8mm for faster printing and hardened hotheads for technical materials

Built-in nozzle wipers

Scrape excess material from nozzles and stop seepage from the currently active extruder to free multi-material prints from smudges and streaks. The extruder can start its print job in the queue without waiting for the currently active one to cool down. Switching between extruders takes much less time, which minimizes downtime.

Tuotetiedot: Snapmaker J1 3D Printer

| Tuotemerkki | Snapmaker |